HLS / WPS

High accuracy levelling and positioning monitoring systems for buildings & large infrastructure

- very high accuracy down to 1 micron

- coverage of large areas

- long-term measurement stability

- resistance to harsh environment

Main features

HLS (Hydrostatic Levelling System) and WPS (Wire Positioning System) are metrology systems used for controlling and monitoring deflection and drift of large buildings and infrastructure. They offer high-precision metrology during construction, operation and maintenance of the structure, even in harsh environments. This solution is field-proven on various infrastructures: synchrotron, bridge, dams, nuclear plant, telescope …

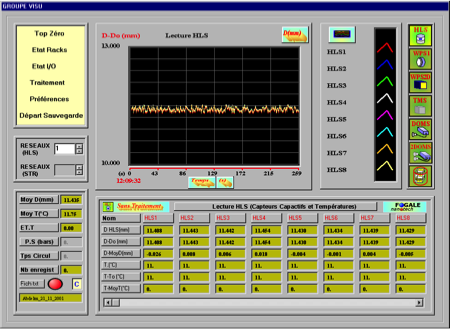

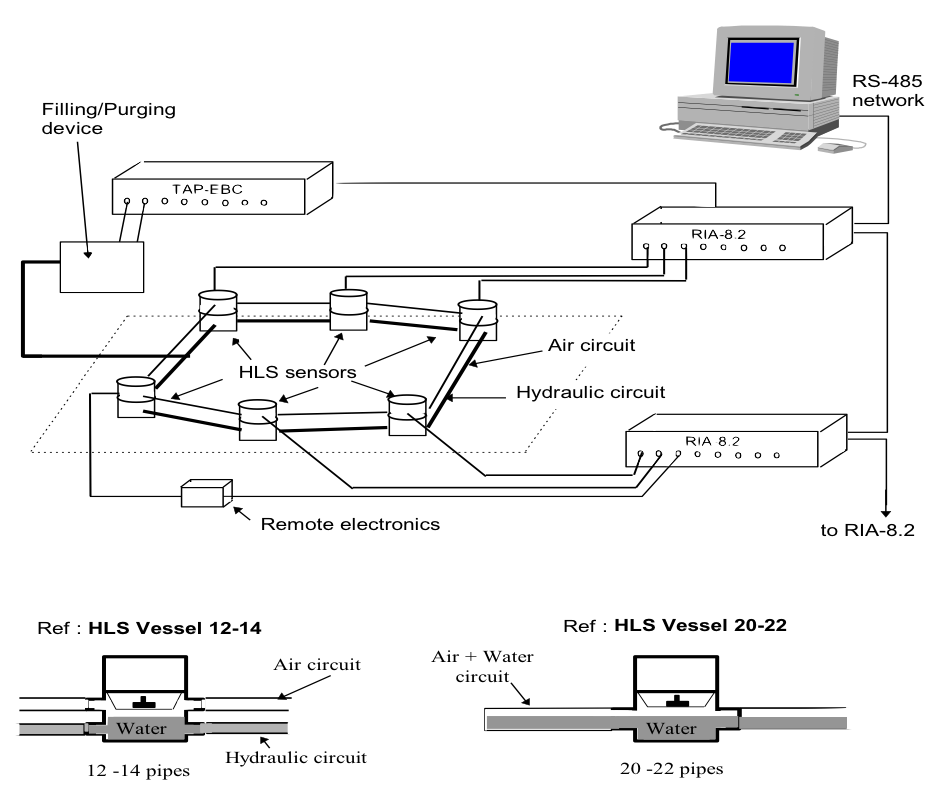

HLS and WPS sensors are networked along the infrastructure or site, and connected to power and data acquisition racks (RIA) that allow continuous data acquisition through a PC system. An optional Multi-system Software Measurement (MSM) allows to check the sensor status and measurement.

Key benefits

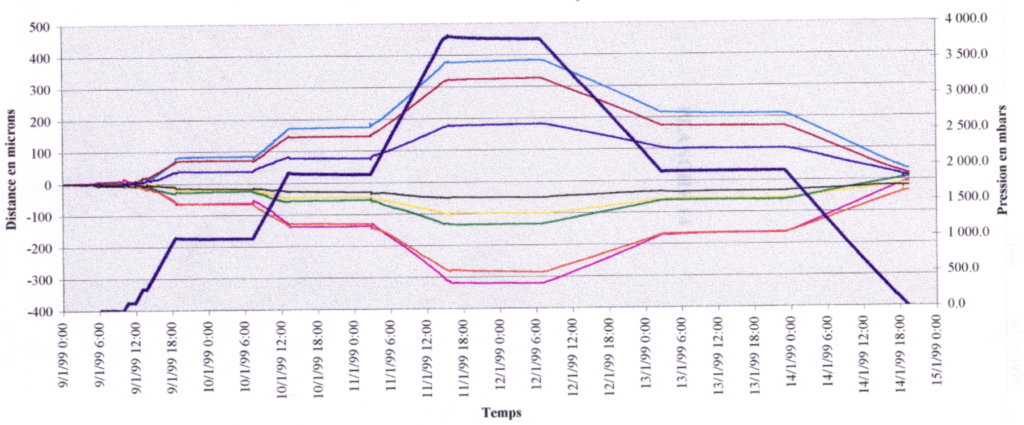

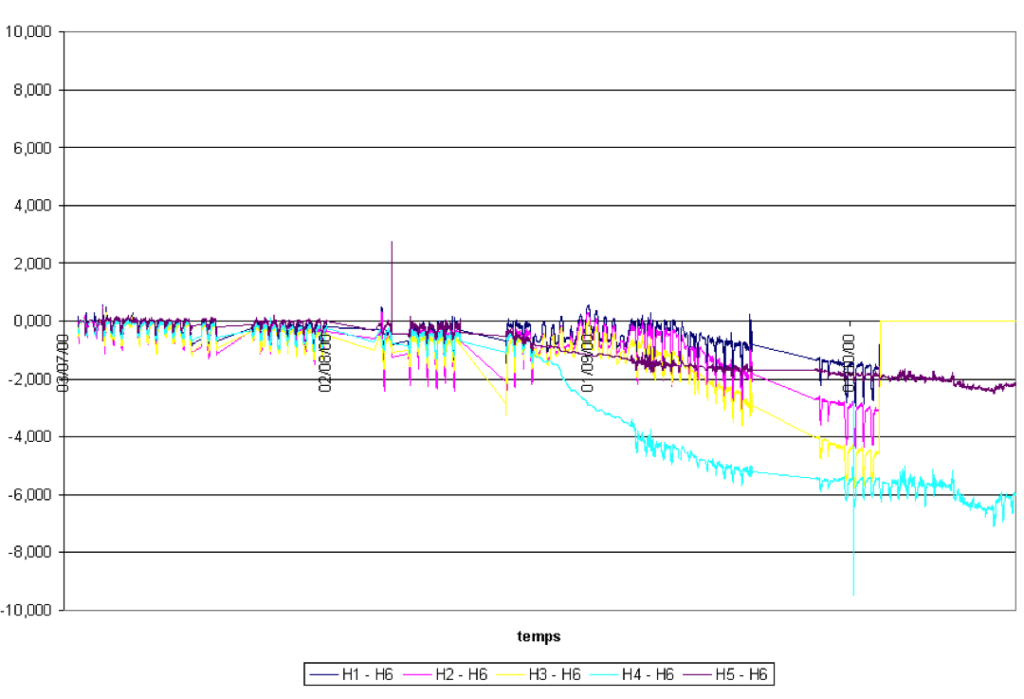

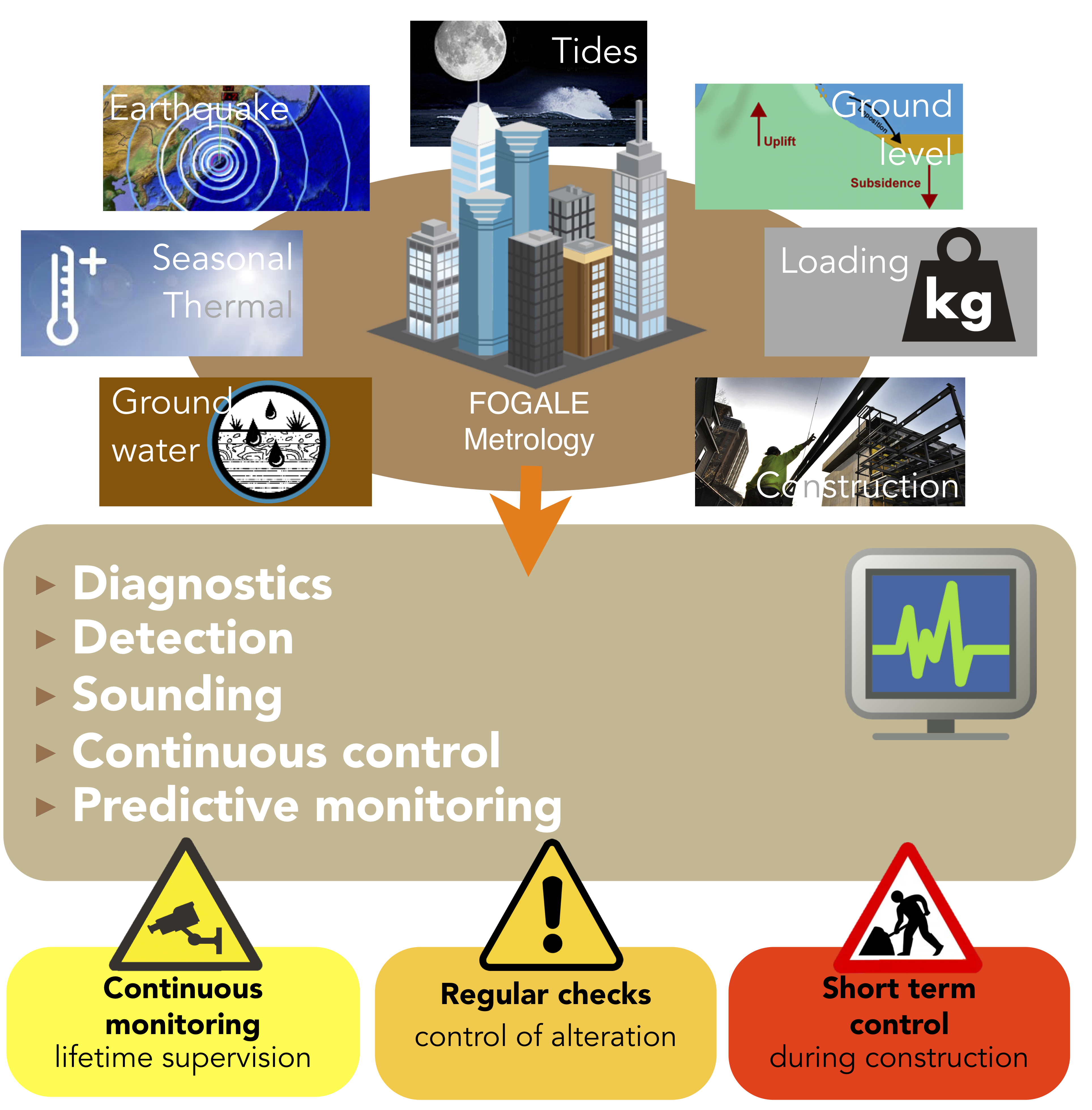

Predictive monitoring: The metrology sensors’ high sensitivity and real-time operation ensures detection of all environmental events: earthquakes, tides, seasonal temperature changes, ground water level, ground level fluctuations, structure loading, construction environment … This allows to identify critical events and make optimised decision to carry-out the necessary safety procedures or maintenance work.

Lifetime supervision: The metrology system is designed to be installed and operate on the structure during a long time. It can also replace laser-based systems for regular checks or short-term controls during construction and maintenance.

Large area monitoring: the networked architecture allows the system to be implemented within areas of several hundred meters or even larger.

Environment resistance: The sensor design is not sensitive to environmental conditions that often affects laser-based systems. These can be used in high radiation environments like nuclear power plants or particle accelerators.

Very high accuracy: Micrometer-range accuracy makes the solution suitable for the control of highly sensitive structures like synchrotrons and large telescopes.

HLS – Hydrostatic Levelling System

- Measurement range: 20-100mm or custom

- Repeatability: 0.5-300 micron

WPS – Wire Positioning System

- Measurement range: 2.5-20mm or custom

- Repeatability: 1-10 micron

RIA – Power & data acquisition rack

- Multi-sensor compatibility

- 16 measurement channels

- Continuous data acquisition

HLS and WPS engineering instrumentation systems makes use of high performance capacitive sensors.

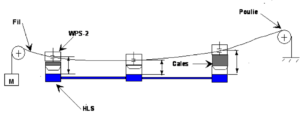

HLS Hydrostatic Levelling System sensors are based on the principle of communicating vessels, with a liquid reservoir as a unique altimetry reference for all the sensors of the system. This allows to take levelling measurements within several hundred meters with an unmatched accuracy.

WPS Wire Positioning System uses a tightened wire as a measuring reference. It measures the wire position in 1 or 2 axis with regard to fixed reference planes within the sensor.

Baseline:

- HLS and WPS sensors, with quantity and positioning according to metrology needs

- RIA power and data acquisition racks, each connected to their sensors

- RS-485 interface to allow networked data communication with a PC

Options:

- Installation support

- MSM Measurement software