Large Telescope Metrology

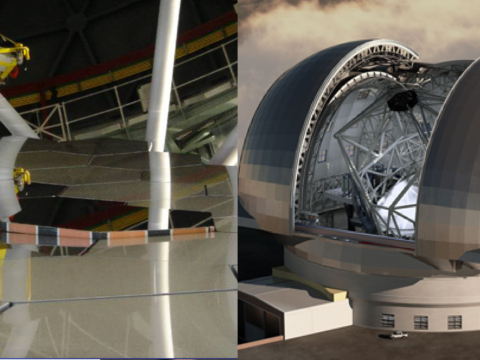

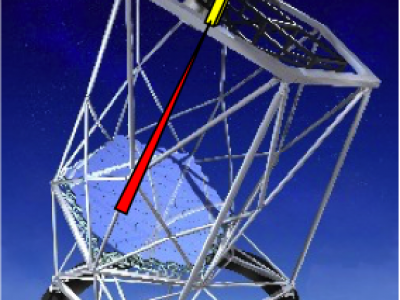

High precision metrology systems for dimensional control of large telescopes

- segmented mirrors positioning

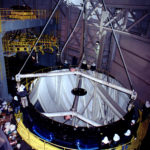

- focus adjustment for primary mirror

- tip-tilt control of adaptative optics & image stabilizer

- delay line rails & Coudé rotating platforms control

Main features

FOGALE metrology solutions for large telescopes allow high precision dimensional control of key elements for an optimal operation of the telescope during its lifespan:

- segmented mirror positioning: tip, tilt, piston, gap and DGRoC measurement

- primary mirror focus and CoC positioning: optical ranging measurement

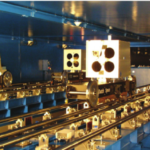

- adaptive optics & image stabilizer positioning: tip-tilt control

- delay line rail and Coudé rotating platform: levelling and alignment

These systems are qualified on the field on several large telescopes.

Key benefits

Edge sensors systems for segmented mirrors makes use of a patented innovative design, allowing unique features:

- Nanometer resolution

- Not sensitive to environment: Edge sensors are not sensitive to humidity and pollution (dust) and offer a very high rejection of condensation, temperature, and electronic perturbations.

- High rejection of gap and tilt variations

Optical ranging measurement solution for primary mirror focus adjustment allows absolute distance measurements offering excellent accuracies at high distances (+/-10 microns at 20m). It is based on LENSCAN metrology solution, which also allows all optical elements positioning with sub-micron accuracy.

Edge sensors and tilt-tilp control systems are customised to each telescope application. Please contact us for detailed enquiry.

LENSCAN and WPS, HLS specifications are detailed in different sections.

Edge sensors are based on the principles of electromagnetic induction and mutual inductance. The design used for the system is patented.

LENSCAN and WPS, HLS technologies are described in different sections.

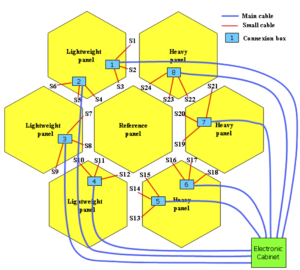

Edge sensor system is composed of:

- a set of edge sensors

- cables and connectors

- an electronic cabinet with analog and digital modules

System layout and configuration depends on mirror design.

Options:

- a numerical modelling software provides 3D analysis of segmented mirrors, 3D modelling of sensors and mechanical strain computations.